Thanks to its resistance to UV radiation, high temperatures and humidity, Fiberlogy ASA is the perfect choice for all 3D printing applications that will be exposed to weather conditions. High mechanical and thermal resistance (up to 94°C) and ease of printing make this material a great replacement for ABS, ensuring its popularity in the automotive industry and in the manufacturing of everyday items.

ASA (acrylonitrile-styrene-acrylate), due to its clearly lower shrinkage than ABS, does not require a heated chamber to ensure a successful print. Unlike its predecessor, ASA gives off much less annoying odours. Less shrinkage and good adhesion prevent the model from curling and cracking and ensure high stability of the print dimensions.

The finished model made with Fiberlogy ASA can be smoothed by exposure to acetone. The material is suitable for sanding and painting. It can also be glued with acetone.

APPLICATION IN 3D PRINTING:

- AUTOMOTIVE: car and motorcycle parts, accessories, substitutes;

- SPORT: guards, sport accessories, spare parts;

- HOME AND GARDEN: decorations, equipment, tools, everyday objects;

- ELECTRONICS: sensor and microcontroller housings.

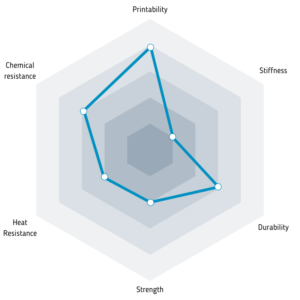

Properties:

- high UV resistance

- high durability

- lasting colours

- resistance to temperatures up to 94°C

- possibility of finished model machining

- low odour emission compared to ABS

How to print?

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

| Nozzle Temperature | 255-270°C |

| Bed Temperature | 90-110°C |

| Closed chamber | not required |

| Fan | 0-25% |

| Flowrate | 90-100% |

| Printing Speed | < 100 mm/s |

| Surface | glass, kapton tape, ABS juice |

| Retraction (direct) | yes, 1-2 mm |

| Retraction (bowden) | yes, 4-6 mm |

| Retraction Speed | 20-45 mm/s |

| Notes | When printing without a heated chamber, it is recommended to avoid exposing the model to gusts of wind/drafts |